“Germany Industry 4.0”, “US Industrial Interne” and “Made in China 2025” gave opportunities and challenges to the manufacturing industry, ICT industry and the development of city. Through the new generation of ICT information technology and the in-depth integration with manufacturing industry, triggering far-reaching industrial changes, assist manufacturing industry to transform and upgrade, thus forming new production methods, new business model and economic growth. The establishment of a highly flexible personalized and digital products and services production model, to achieve smart factories, smart production and smart service.

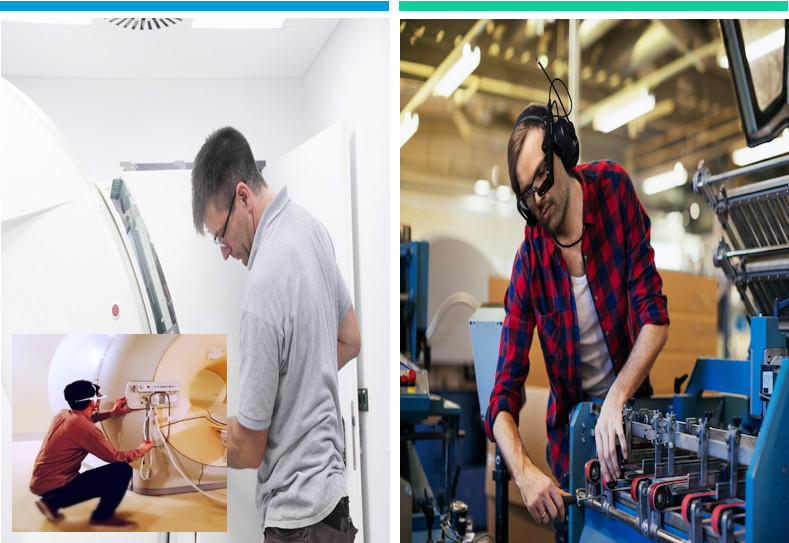

√ Provide remote technical maintenance and trouble shooting, reduce the incidence of equipment downtime.

√ Remote training, improve the skills of new employees.

√ Accurate equipment inspection , preventive data maintenance, visual safety report.

√ Save a lot of time and labor cost.